Lean construction is a process that works to continually improve the method of project delivery. Its goals are to eliminate waste, improve processes, and create more collaboration among project team members.

Lean construction came out of the Toyota manufacturing facilities after World War II. It was used to improve and shorten the manufacturing time for automobiles. Construction has adopted many of the principles of the process to increase efficiency.

Pull planning is a tool from lean construction that seeks to optimize the project schedule. It’s a different way of thinking about project schedules that allows teams to reduce waste, meet deadlines, and shorten project schedules.

Pull planning is a schedule creation method that is focused on collaboration. All members of the project team participate in schedule creation, creating buy-in and a sense of ownership. The method works by scheduling the project backwards, from finish to start.

The critical path method, or CPM, is usually created by one person, with or without input from team members. The schedule is handed out to the project team, and everyone is expected to meet it. The schedule is created by working the project from beginning to end, sequentially.

Pull planning encourages team members to work together to tackle schedule challenges. Meetings are held on a regular basis to ensure that the schedule is being met and problems are being addressed. These regular meetings help improve communication among team members.

Everyone participates in the development and monitoring of the construction schedule. There is open communication among all team members during update meetings, and members work together to address problems. Open communication ensures that everyone knows how each other is doing on the project, so there are less surprises.

Pull planning reduces rework caused by mistakes or miscommunication. It also reduces subcontractor standby time waiting for work to be completed by others. There are fewer change orders on projects that use pull planning, as there is more open communication among team members.

Every team member participates in schedule creation and regular updates. Project owners and designers are included in this process from beginning to end.

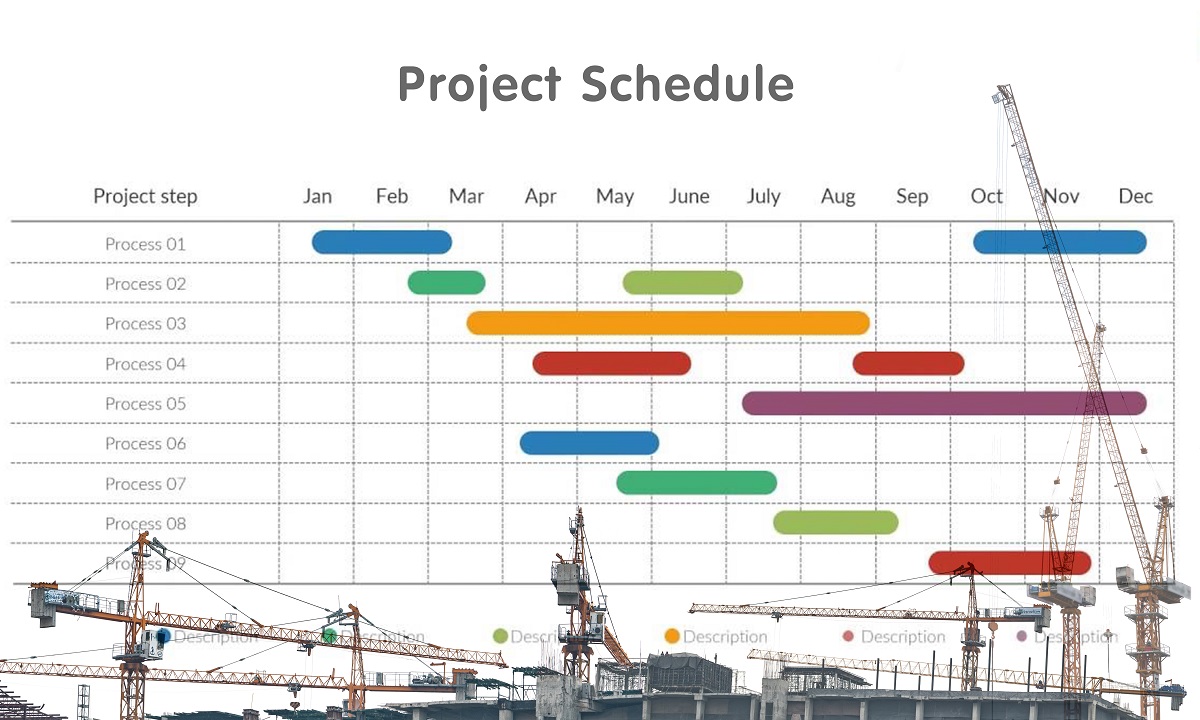

Lay out the project milestones and deadlines and create a timeline on a large whiteboard to represent the progress of the project. While most teams use a low-tech method to create their schedules, there is technology and software available to perform the task electronically.

The team works together to determine the tasks that need to be completed to meet the project intentions. Planning starts at the end of the project and moves toward the beginning. Each activity is represented by a color coordinated sticky note, with each team member represented by a different color. In this initial planning, task durations are not included.

Next, task durations are assessed and added to each sticky note. In addition, the sticky note includes information on what has to be completed before the activity can begin. This helps the team identify critical tasks.

The team collaborates to create a schedule that meets the milestones and deadlines and that everyone buys in to. Dates and durations are modified to meet the schedule requirements.

Each week a weekly plan is developed with the activities that are being worked on that week. These weekly schedules are reviewed by all team members in a cooperative meeting, and changes are made as needed.

Daily morning meetings are used to review the tasks in process that day and ensure that they are being completed as planned.

As changes occur, the daily, weekly, and overall project schedules are updated.

Although lean construction is about more than just pull planning, this scheduling technique can save contractors time and money. The process schedules work on a project from finish to start, allowing teams to address critical tasks, and is collaborative, allowing everyone to have a voice in the schedule and create buy-in. Other lean construction tools, such as just in time deliveries, prefabrication, and the use of building information modeling (BIM), can help project teams improve their efficiency and manage the risks of construction more effectively.