Ensuring workplace safety is crucial for preventing accidents, illnesses, and injuries. A key component of this is effective workplace hazard recognition. OSHA standards and guidelines provide a comprehensive framework for identifying and managing hazards. Additionally, incorporating SMART goals into safety training can significantly enhance the effectiveness of these efforts.

OSHA’s mission is to guarantee safe and healthful workplaces for employees through standard-setting, enforcement, and training. Employers must adhere to OSHA standards and the General Duty Clause to maintain hazard-free workplaces. Compliance with these standards is essential for effective workplace hazard recognition and management.

OSHA Standards for General Industry

OSHA’s 29 CFR Part 1910 sets safety standards for general industry, covering manufacturing, warehousing, utilities, and services. Key regulations include:

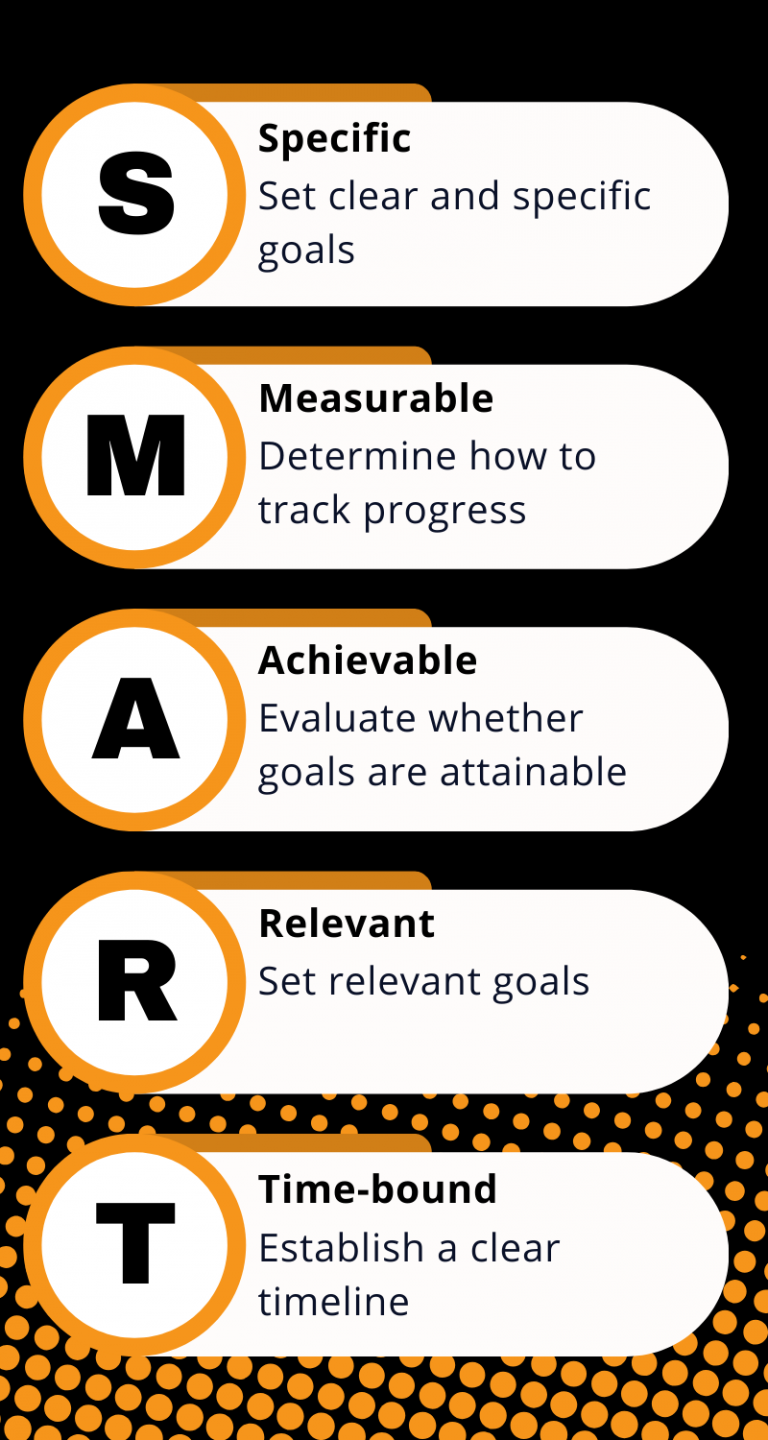

Specific, Measurable, Achievable, Relevant, and Time-bound SMART goals effectively ensure sound and practical safety training. Implementing SMART goals can significantly enhance workplace hazard recognition and management.

Specific

Set clear and specific goals to define what you need to achieve, who is responsible, and what steps you should take. For instance, aim to have all warehouse employees complete forklift safety training by the end of the quarter.

Measurable

Determine how to track progress. Use software to monitor training completion rates or analyze post-training assessment scores to ensure adequate workplace hazard recognition.

Achievable

Evaluate whether the goals are attainable within the set timeframe. Ensure employees have the necessary resources to achieve these goals. For example, provide the required materials and support for training sessions.

Relevant

Set goals that are relevant to the workplace and current safety needs. For example, if hand injuries have increased, focus on hand safety training. This relevance ensures that workplace hazard recognition efforts are meaningful and impactful.

Time-bound

Establish a clear timeline for achieving the goals. It helps maintain accountability and ensures timely training. For example, aim to complete all safety training sessions by a specific date to ensure continuous improvement in workplace hazard recognition.

Using SMART goals in safety training involves several steps:

Identify specific safety hazards or areas for improvement.

Communicate these goals to all relevant parties, explaining the importance and impact of each goal.

Measure progress and adjust the goals as needed based on feedback and results.

For example, if a company has noticed an uptick in hand injuries, it’s a team effort to set a goal. Safety managers, in collaboration with all employees, might set a goal to have everyone participate in at least two safety meetings focused on hand safety by the end of the month. This goal, specific, measurable, achievable, relevant, and time-bound, is a perfect example of using SMART goals to enhance workplace hazard recognition, and it’s a testament to the inclusive, team-based approach to safety.

While SMART goals are practical, people can misapply them. Common pitfalls include:

Failing to communicate the goals.

Not making the goals relevant to the workplace.

Additionally, setting realistic goals or inflexible timelines can help progress. It’s crucial to remain flexible and adjust goals based on feedback and results.

Workplace hazard recognition and practical safety training are critical for ensuring a safe and compliant work environment. Employers can significantly enhance workplace safety programs by adhering to OSHA standards and incorporating SMART goals into safety training. These efforts protect employees and promote a culture of safety and responsibility within the organization. Implementing these strategies ensures that workplace hazard recognition remains a priority, ultimately leading to a safer and healthier work environment.